[pullquote]Our CEC crew completed 26 CEC projects in 2015, bringing our total number of CEC projects to 158 since 2010![/pullquote]In 2015 we celebrated Chuckanut Builders 5th birthday, hired 4 new crew members, brought interior architecture in-house, completed our 170th Community Energy Challenge and we worked on a handful of technically interesting and beautiful jobs.It was a fun, full year. Check out our where the money went chart, photos from the year below and a few other random highlights.

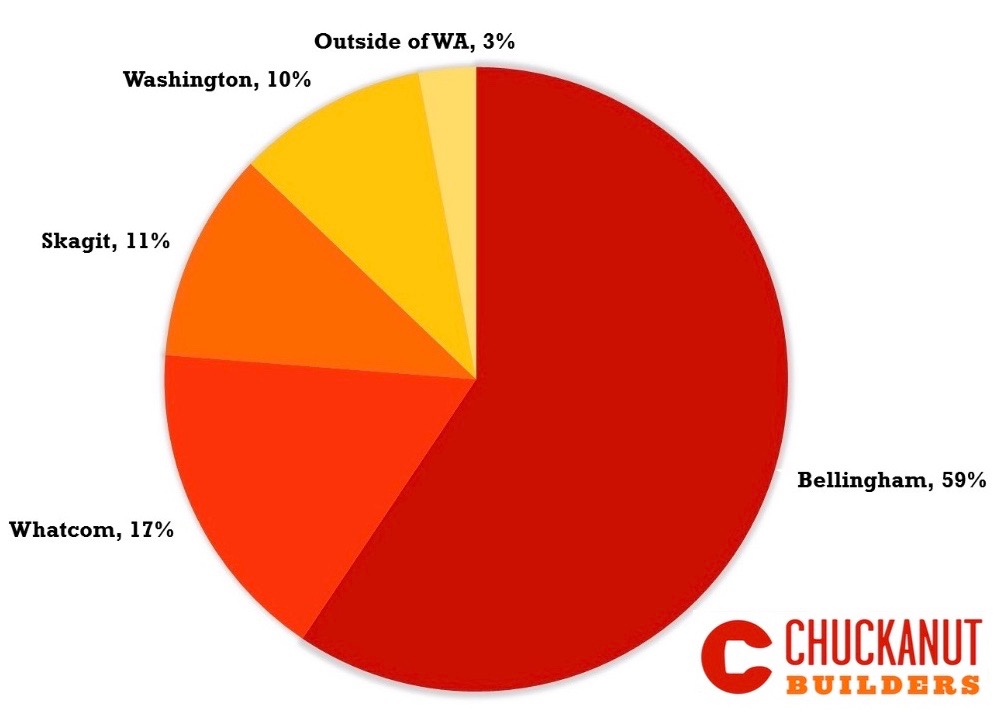

Where the money went-

- In 2016 87% of our spending was in Whatcom and Skagit County. Of that 59% was spent in Bellingham.

- Only 3% of our spending was at businesses with headquarters outside of Washington!

- Interestingly, the vendors that we spent the most with were two cabinet shops, two electricians and of course Bellingham Millwork and Hardware Sales!

Cool projects-

- We completed one of our most interesting CEC projects to date this year. We added external insulation and live edge siding to a log home house, dramatically increasing the efficiency and comfort of the home. We also completed extensive air sealing and installed a weather proof barrier. Details here.

- Our crew spent some quality time at the Public Market this fall remodeling the new Film is Truth space!

- Early in the year we worked on the Whatcom Center for Early Learning building, remodeling the office space and completing extensive building performance measures. Our crew worked with Artworks Construction to match the existing, historic trim details which are so beautiful!

- This beautiful, modern project was definitely a highlight of 2015. We worked closely with [bundle] design, Bourne Engineering, Smith and Vallee Woodworks and a handful of awesome subcontractors on this beauty.

Photos of the year-

[metaslider id=5601]

Giving back-

- [pullquote]In 2015 our crew made 723 trips to Hardware Sales and 200 trips to Bellingham Millwork.[/pullquote]This spring the Downtown Bellingham Partnership was ready for a facelift and we were happy to help. A handful of local businesses were involved in the project, our contribution was a ‘toast’ bar made out of our signature bowling alley slab.

- Make.Shift needed some help sound proofing their recording studios and Cole Miller, our then Building Performance Manager, was happy to help. He added nearly 20 bags cellulose insulation and from the sounds of it, it helped!

- Once again, Forest was the mastermind of the String Band Jamboree stage. A handful of the crew helped build the stage and of course spent a long weekend listening to great music and enjoying the Jamboree!

by Intellitonic

by Intellitonic